Editor’s Note: This piece references Forbes’ feature “The Footwear Brand Using AI to Revolutionize Shoemaking” by journalist Anna Haines. The story explores how IAMBIC merges artificial intelligence, biomechanics, and craftsmanship to redefine precision-fit footwear.

IAMBIC designs AI-powered, precision-fit footwear that unites data, biomechanics, and European craft. Each pair begins with a smartphone 3D scan capturing more than twenty biometric data points. Our Fit Engine converts this data into a digital last shaped to your anatomy, then artisans in Portugal build your pair for balance, alignment, and endurance.

Recognized as a TIME Best Invention and supported by the National Science Foundation, IAMBIC continues to lead the evolution of fit through innovation and design.

Forbes spotlight: The footwear brand using AI to revolutionize shoemaking

NEW YORK, NY — Forbes profiles how IAMBIC applies AI-assisted, NASA-grade design to eliminate poor fit in footwear. Before mass production, every pair was crafted to the individual. Today, most shoes are built around standard sizes, and our feet feel the consequences. Across 18 studies, researchers found that 63% to 72% of adults wear ill-fitting shoes, contributing to pain and performance decline.

“Have you ever had a custom-made shoe?”

Anna Haines, Forbes

The story follows IAMBIC’s origins in founder Maeve Wang’s search for shoes that fit and shows how data, biomechanics, and craft unite to deliver comfort that performs all day. Explore the technology.

Why standard sizing fails and how AI changes the outcome

Traditional sizing ignores the complexity of human feet. IAMBIC’s AI Fit Engine maps 3D geometry to predict pressure points, balance, and alignment. The result is footwear that fits precisely and supports performance, whether walking, presenting, or traveling.

“Most shoes start from a fixed size chart and a static last.”

Maeve Wang in Forbes

With AI-driven geometry, IAMBIC eliminates compromises between comfort, movement, and professional presentation.

How the IAMBIC system works

- Order MODEL T. Start from the product page.

- Complete your Virtual Consultation. After checkout, you’ll receive a link to capture three images per foot and complete your comfort profile.

- Receive your pair. Each order is handcrafted in Portugal and shipped in about four to six weeks.

- Balanced pressure: Data-optimized load distribution.

- Locked-in comfort: Geometry matched to your foot’s architecture.

- All-day performance: Stability that supports focus and endurance.

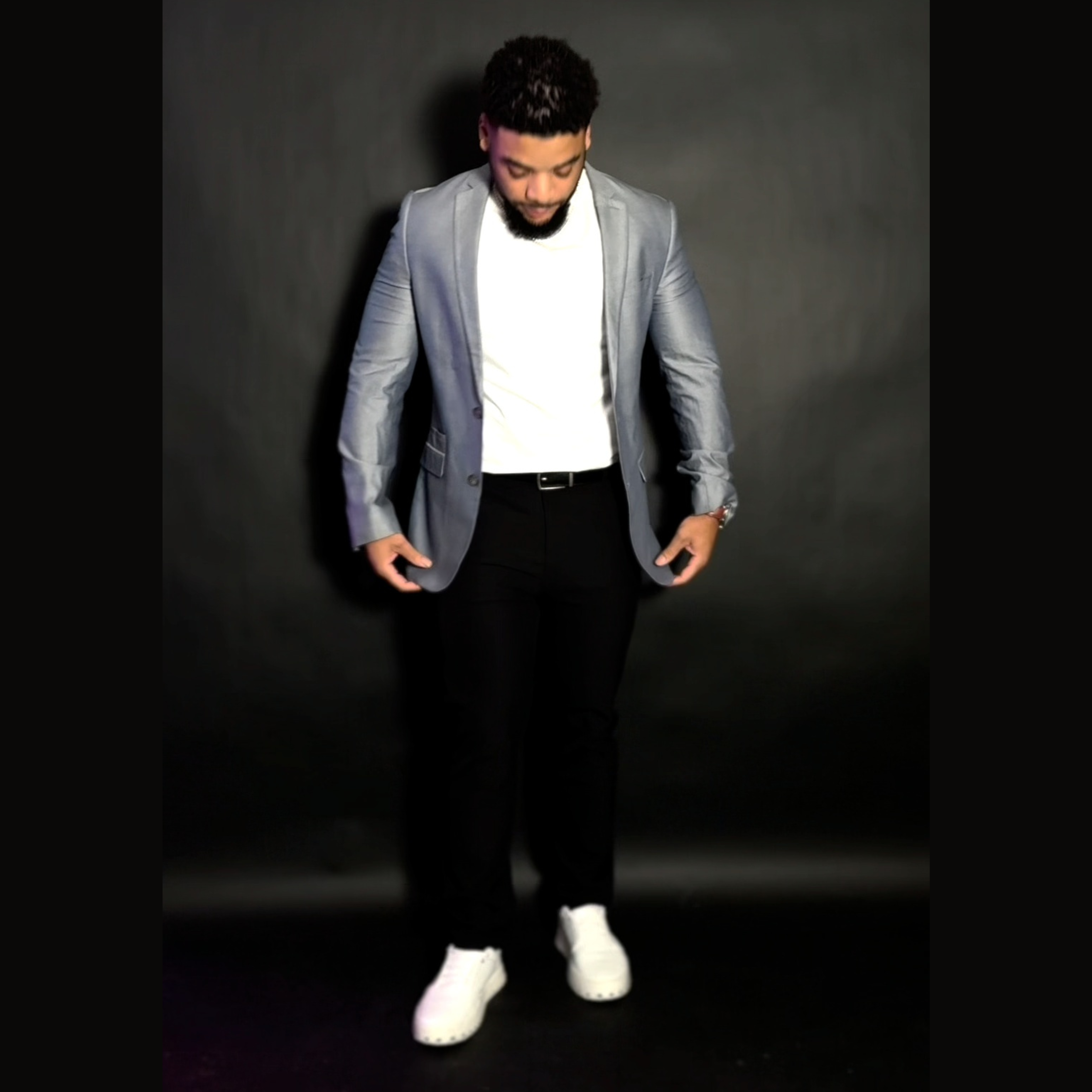

Engineered for leaders who move

Every step influences posture, focus, and energy. IAMBIC’s AI system reads twenty or more biometric variables to improve balance and reduce fatigue. This precision-fit approach has made IAMBIC the choice for executives seeking luxury performance footwear that supports demanding days.

Precision that reduces waste

IAMBIC’s made-to-order model prevents overproduction and reduces returns by ensuring each pair is built for a specific customer. Every shoe has an owner before it exists, aligning sustainability with craftsmanship and performance longevity.

“Precision fit means each pair has an owner before it is made.”

IAMBIC Engineering

About the Forbes Author

Anna Haines is a lifestyle journalist covering wellness, travel, food, and design for outlets including Architectural Digest, Bloomberg, Vogue, and Travel + Leisure. Her reporting focuses on innovation across culture and lifestyle industries.

The most interesting thing about them being crafted just for me is how well they fit. And I had never even noticed that my shoes didn't fit right. My other shoes don't hurt me - they just slosh around. With these, the heels actually stay on the whole time and it fits snugly yet still comfortably. And I'd never experienced that before. They just stay comfortable all day.

As a runner, as an athlete, just knowing that I'm doing a good service to my body is incredible. It’s the reason that I love my IAMBIC shoes. It's that precision that makes me feel safe to walk down the street, get on the subway, do my commute, bring my kids to school, and not feel concerned that I'm doing it in a shoe that doesn't fit right or that doesn't feel good.

The thing that I was surprised by the most with the precision fit is that any pressure points that I had been feeling with the shoes that I previously came in wearing were completely gone. I was wearing a shoe that wasn’t too tight. It wasn’t too loose. The sole fit just right. Total comfort. That’s the best way to put it.

I deal with chronic foot pain, and a lot of it comes from shoes that do not really fit. When I wear my IAMBICs, I notice less pain and they are incredibly comfortable. I do not worry about support, and I even get compliments on them when I am out, which feels great.

A lot of shoes feel fine for a short walk but not for hours. What I like about IAMBIC is that it feels snug and comfortable, yet substantial enough for long walks without discomfort. That matters to me, and the shoe has really delivered on that.

The first time I tried my IAMBICs, I noticed the difference right away. I have small feet, so most shoes either do not fit or are uncomfortable somewhere. Knowing these were tailored to my foot was meaningful. They are truly comfortable and still versatile in style, which is rare to find.

I think we’re all placed on this earth as unique individuals. None of us are really off the rack in terms of sizing. So for me to have that experience of having something made specifically for me that fit perfectly was something that was a little bit mind blowing. And once I got the shoes, I tried them on, they looked great, they felt great. And honestly, they fit like a glove.

In motorsport, a millimeter matters. My IAMBICs are built with that same precision, and you can feel it when you move. They remind me of the exactness you find in high-performance machines, translated into footwear.

With IAMBIC, I can be on my feet through long shoots without that usual end-of-day fatigue. I do not worry about burning out or feeling drained like I used to. They help me get through overtime and long days without thinking about pain.

They move with me and quickly became part of my day. I do not wear them only for style, I wear them because they make me feel good. The comfort and support are what keep me reaching for them.

With most shoes I am always wishing I had chosen something else. With IAMBIC, I don’t think about switching. I want everything else to feel the way these do, because they are the pair I reach for every day.

When I wear my IAMBICs, I barely notice them, and I think that says everything. The difference shows up when I switch to other high-end sneakers and immediately feel the discomfort. They fit my feet so well that comfort just feels natural.