Summary

In this video, we share the early thinking behind IAMBIC’s approach to fit, starting with the idea that better matching could connect people to the right shoes at scale. As we built a smartphone-based foot scanner and tested across categories, we learned something important: fit is not only a data problem, it is a design and manufacturing problem. That insight led to a pivot, taking the principles of custom-made shoes and combining them with ergonomic design, AI, advanced manufacturing, and modularity to make precision fit more accessible.

Key Takeaways:

- The original hypothesis was simple: match personal preferences and foot data with shoe data using analytics and machine learning.

- Building a smartphone-based foot scanner and testing across shoe categories revealed a deeper issue than matching alone.

- The true bottleneck is design and manufacturing, not only data alignment.

- Improving existing shoes through fit data would take up to 10 years to impact what people wear day to day.

- Custom-made shoes offer fit and luxury, though they are typically expensive and slow to produce.

- IAMBIC pivoted to create its own shoe brand, merging custom principles with ergonomic design, AI, advanced manufacturing, and modularity.

Transcript

We all work together to get a National Science Foundation Grant and to build our smartphone-based foot scanner and we started testing this with shoes across sneakers, hiking boots, dress shoes, and we realized that data matching is not the solution, it is actually a design and manufacturing problem that we need to address.

If we wanted to focus on foot data and how that could improve the design, improve the manufacturing techniques, then we calculated it would take up to 10 years for us to finally impact the physical shoes that you and I would put on our feet. And we reflected. We reflected on actually going back to the individual and thinking about custom-made shoes. Today, they cost between three to ten thousand dollars, take between three to twelve months to make, but if we could take those principles, fit and luxury, and merge them with scientifically proven benefits of ergonomic design, and leverage these amazing technologies around AI and advanced manufacturing and modularity, then perhaps we could make that accessible for the everyday shoe. And so that was when IAMBIC decided to pivot to our own shoe brand.

The most interesting thing about them being crafted just for me is how well they fit. And I had never even noticed that my shoes didn't fit right. My other shoes don't hurt me - they just slosh around. With these, the heels actually stay on the whole time and it fits snugly yet still comfortably. And I'd never experienced that before. They just stay comfortable all day.

As a runner, as an athlete, just knowing that I'm doing a good service to my body is incredible. It’s the reason that I love my IAMBIC shoes. It's that precision that makes me feel safe to walk down the street, get on the subway, do my commute, bring my kids to school, and not feel concerned that I'm doing it in a shoe that doesn't fit right or that doesn't feel good.

The thing that I was surprised by the most with the precision fit is that any pressure points that I had been feeling with the shoes that I previously came in wearing were completely gone. I was wearing a shoe that wasn’t too tight. It wasn’t too loose. The sole fit just right. Total comfort. That’s the best way to put it.

I deal with chronic foot pain, and a lot of it comes from shoes that do not really fit. When I wear my IAMBICs, I notice less pain and they are incredibly comfortable. I do not worry about support, and I even get compliments on them when I am out, which feels great.

A lot of shoes feel fine for a short walk but not for hours. What I like about IAMBIC is that it feels snug and comfortable, yet substantial enough for long walks without discomfort. That matters to me, and the shoe has really delivered on that.

The first time I tried my IAMBICs, I noticed the difference right away. I have small feet, so most shoes either do not fit or are uncomfortable somewhere. Knowing these were tailored to my foot was meaningful. They are truly comfortable and still versatile in style, which is rare to find.

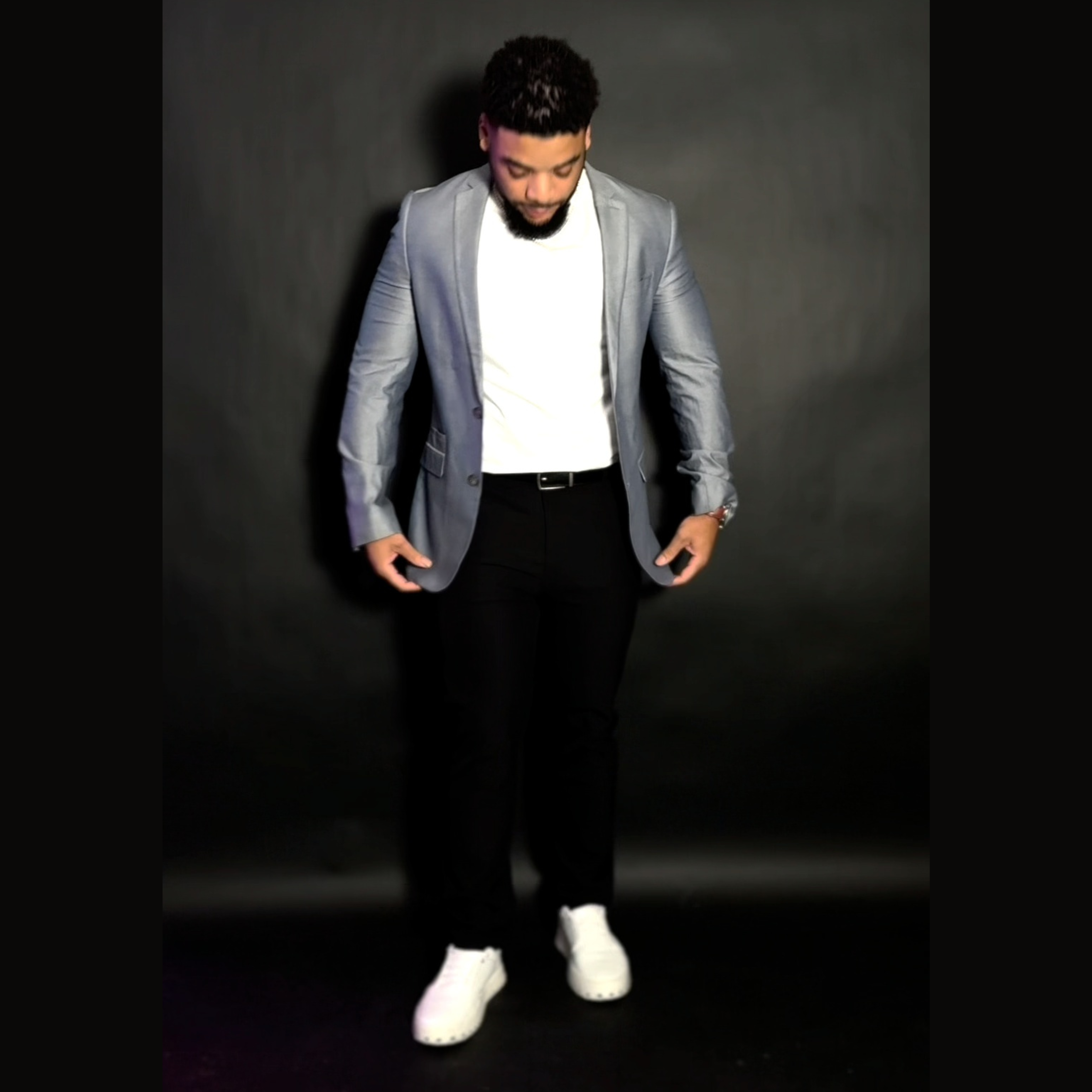

I think we’re all placed on this earth as unique individuals. None of us are really off the rack in terms of sizing. So for me to have that experience of having something made specifically for me that fit perfectly was something that was a little bit mind blowing. And once I got the shoes, I tried them on, they looked great, they felt great. And honestly, they fit like a glove.

In motorsport, a millimeter matters. My IAMBICs are built with that same precision, and you can feel it when you move. They remind me of the exactness you find in high-performance machines, translated into footwear.

With IAMBIC, I can be on my feet through long shoots without that usual end-of-day fatigue. I do not worry about burning out or feeling drained like I used to. They help me get through overtime and long days without thinking about pain.

They move with me and quickly became part of my day. I do not wear them only for style, I wear them because they make me feel good. The comfort and support are what keep me reaching for them.

With most shoes I am always wishing I had chosen something else. With IAMBIC, I don’t think about switching. I want everything else to feel the way these do, because they are the pair I reach for every day.

When I wear my IAMBICs, I barely notice them, and I think that says everything. The difference shows up when I switch to other high-end sneakers and immediately feel the discomfort. They fit my feet so well that comfort just feels natural.